- Home /

- Projets /

- Dream Works /

- FRIEX

FRIEX

A combination of friction and explosion

Fully automated welding of high-pressure pipelines through a combination of friction and explosion.

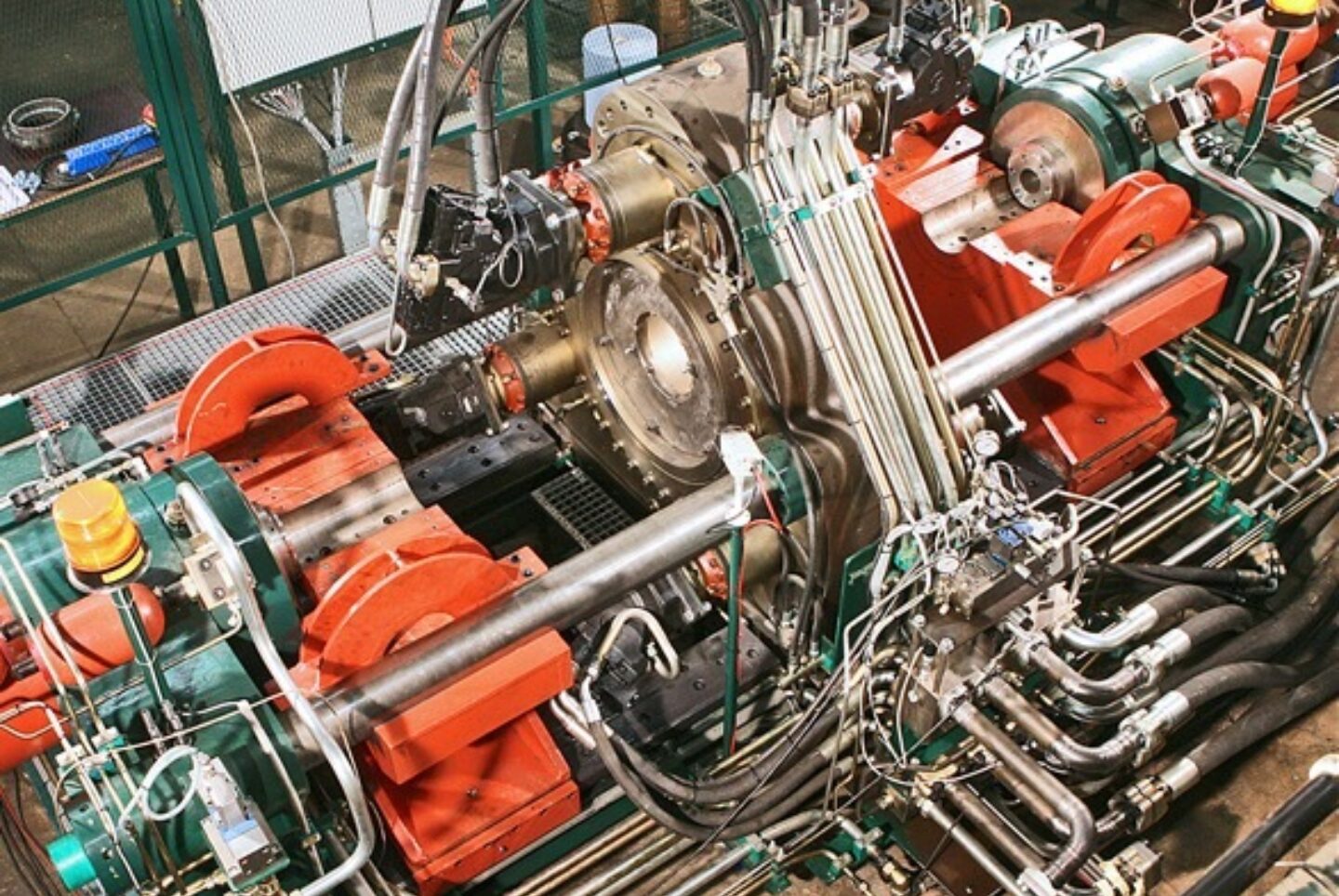

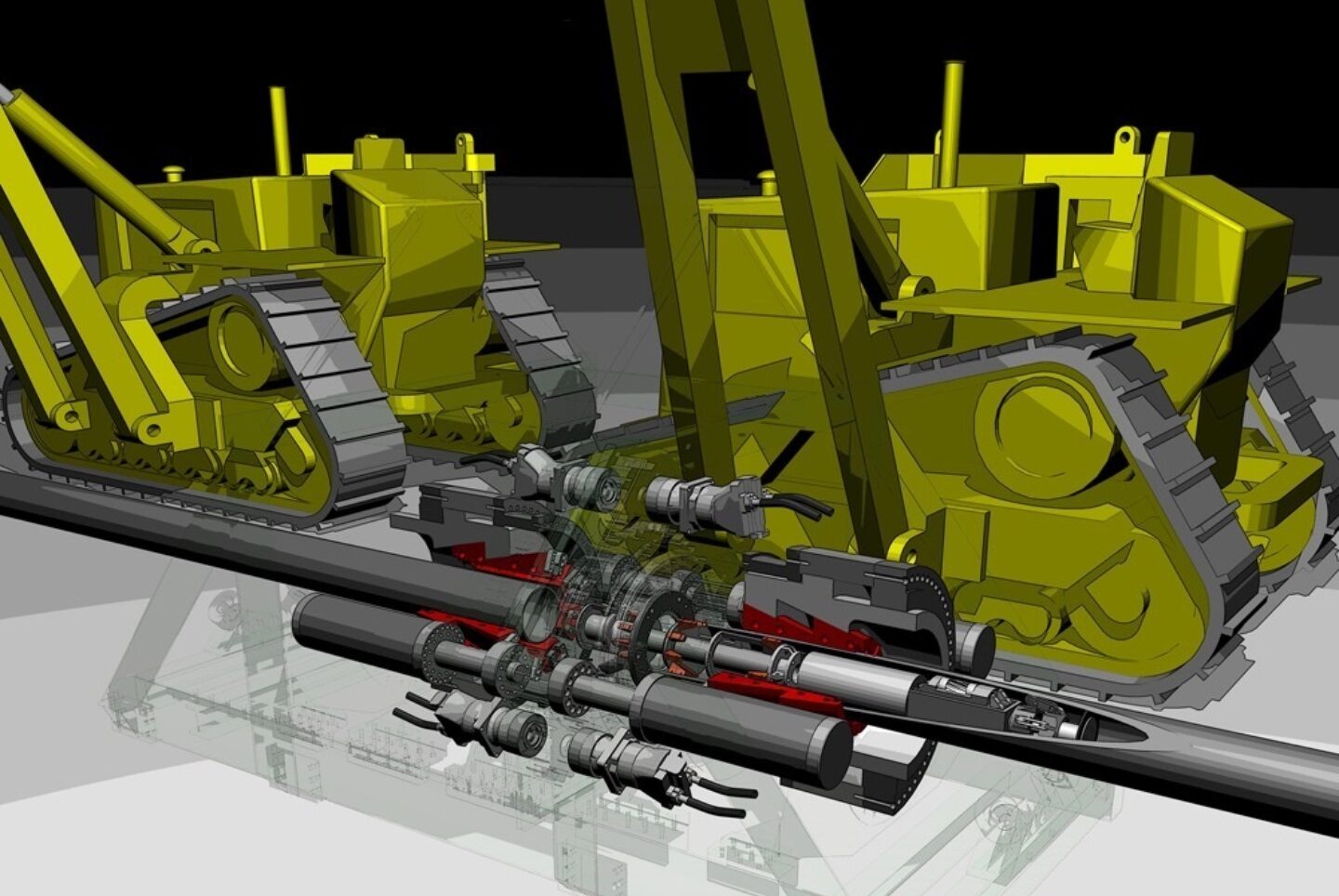

The groundbreaking automated welding process FRIEX is the result of eight years of research with the support of the IWT and intensive cooperation between Denys, BIL (the Belgian Welding Institute) and the Laboratory Soete at the University of Ghent. The prototype of the welding machine for pipes up to 500 mm is operational in our workshop and produces good welding results.

Pipeline steel is something special. It has a very low carbon content: < 0.09 % and it is micro-alloyed. In order to achieve a minimum yield strength of 480 MPa, which corresponds to X70 in industry jargon, steel manufacturers apply various modern techniques during the manufacturing process. In this way the steels are hardened and tempered whether thermomechanically or normally rolled in order to increase tensile strength, to control ductility and ensure impact toughness.

When welding, due to the introduction of heat, there is a risk that the aforementioned artificial strength properties could be destroyed. This is why the welding method for each project must be re-approved (PQR - Procedure Qualification Record).

The conventional welding process as applied today in the pipeline world is a fusion welding process, where the metal is brought to melting temperature. Here filler material such as electrodes and welding wire are used and shielding gases are added to protect the arc against oxidation.

The heat input in the HAZ or heat-affected zone and the welding metal is highly dosed in order to obtain the desired tensile strength, ductility and impact toughness. Furthermore, during the fusion welding process, chemical reactions occur in the molten pool that must be controlled.

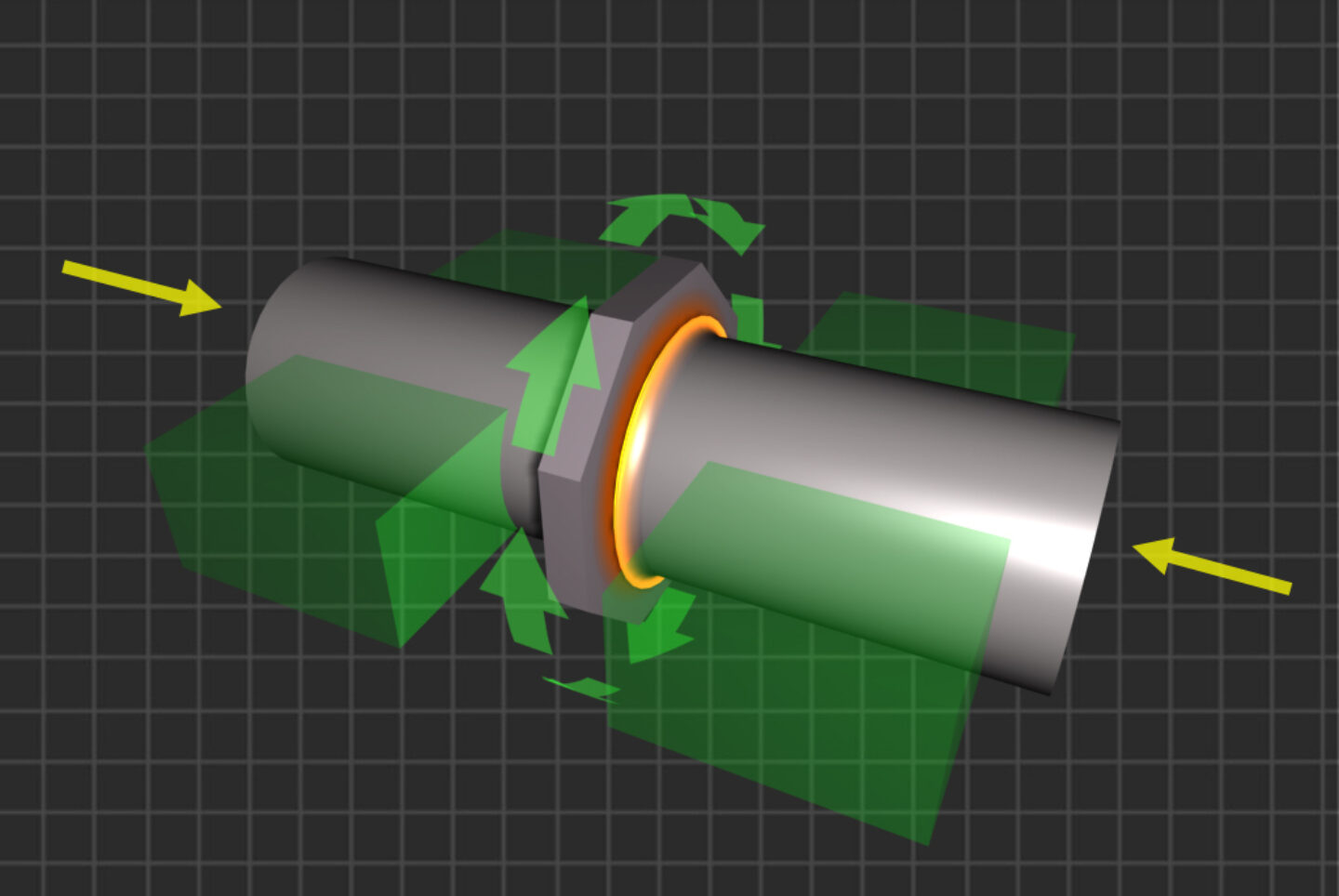

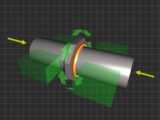

Friex, the new welding process from Denys, is a friction and forge welding process without a melting phase and is therefore called a fixed phase welding process.

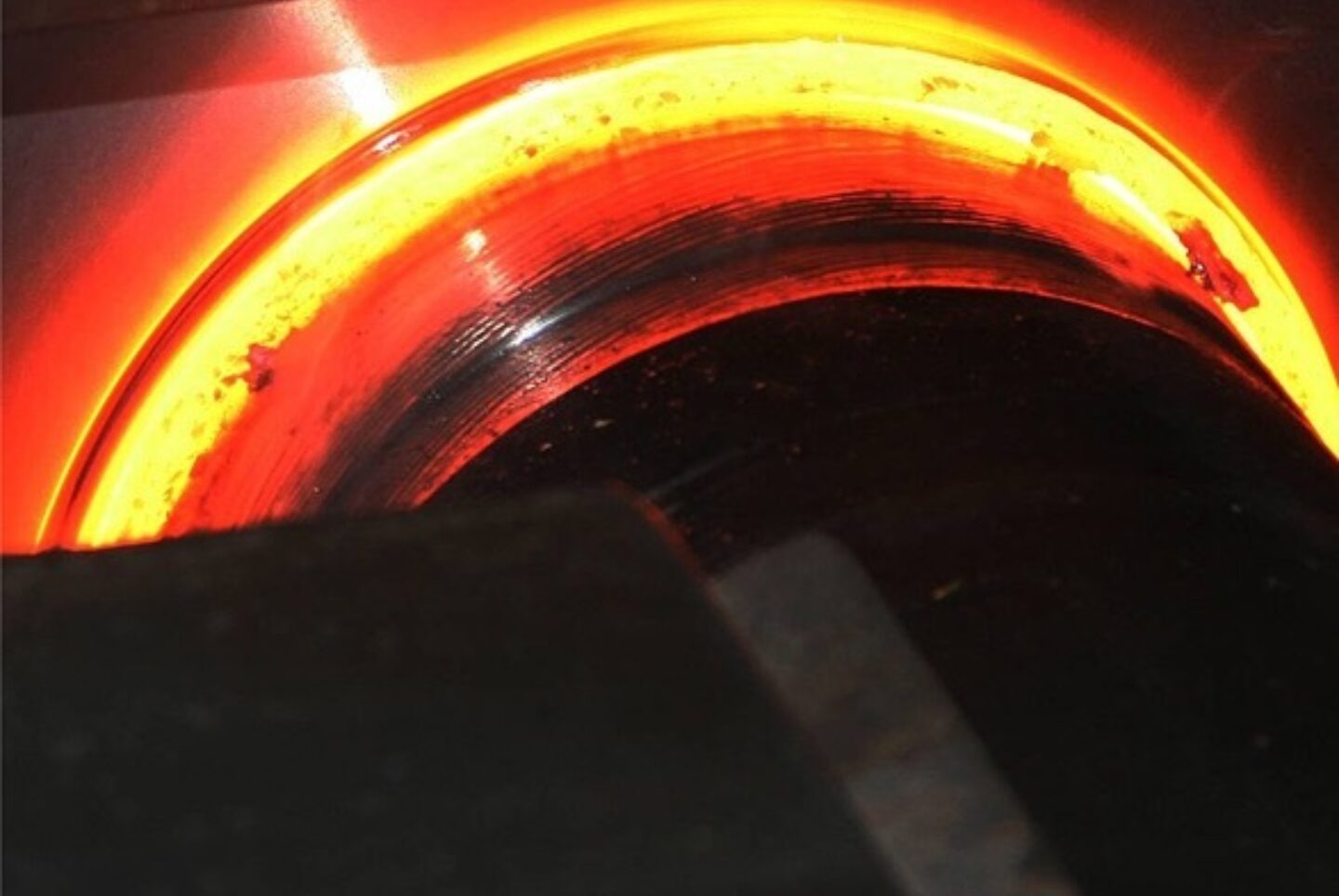

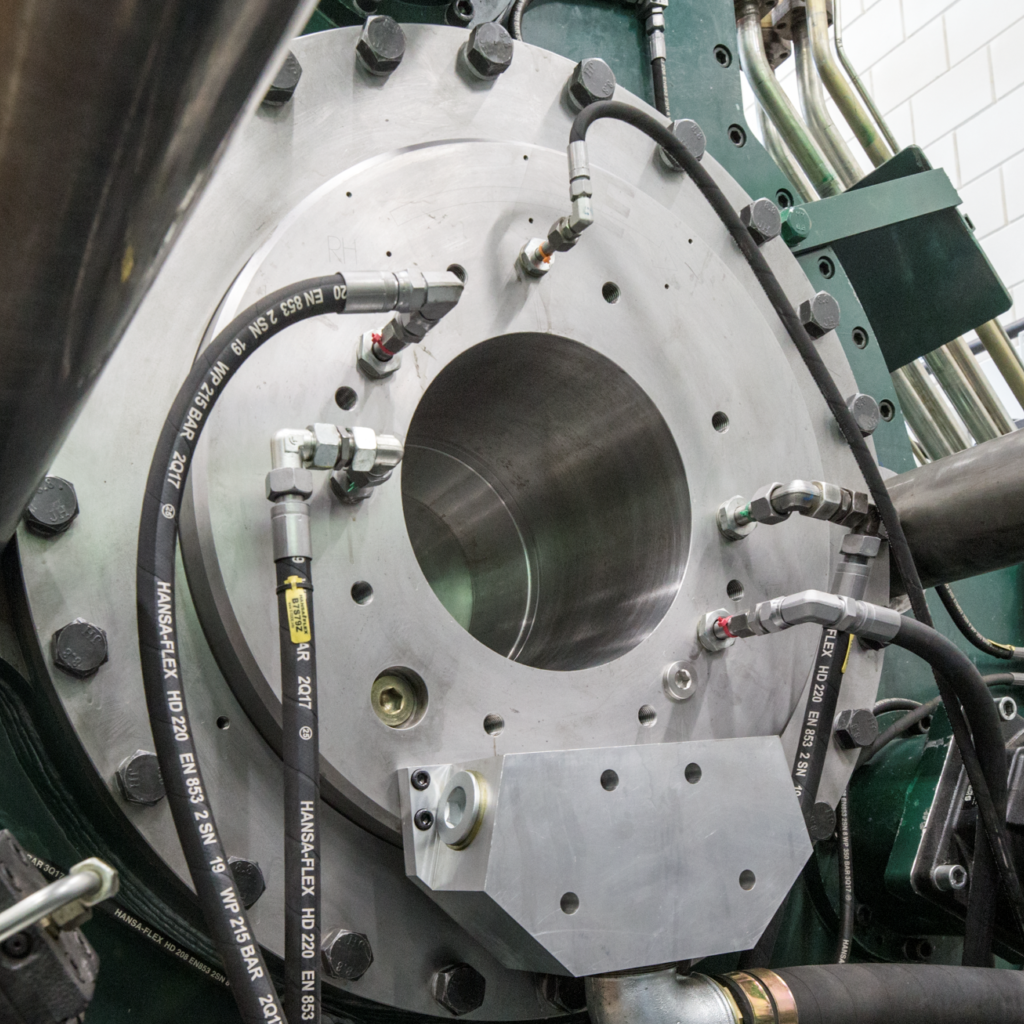

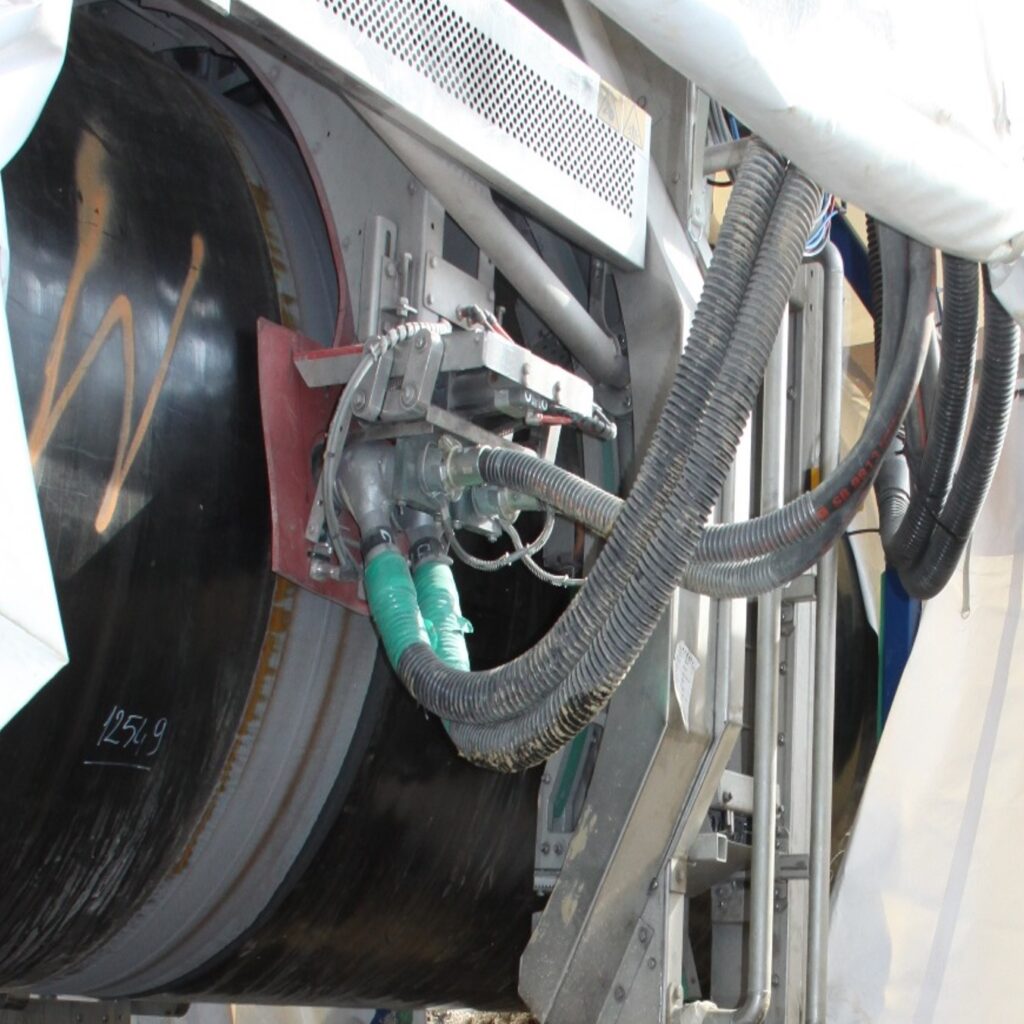

The heat input is automatically controlled by close monitoring of the parameters. By applying axial pressure to the metal piping and by the relative motion between the rotating welding disc and the tube ends, heat is generated on the friction surfaces. The energy required to overcome friction and to break the adhesion between the friction surfaces is converted into heat. As the heat increases on the contact surfaces, the friction resistance is reduced by increasing the plasticity of the metal.

Under the influence of the axial pressure on thepipes a welding burr arises on the an inner and outer wall of the pipe. The impurities in the contact faces are forced out. When this heating and purification process has developed sufficiently, the rotation motion is abruptly stopped and the explosive forge pressure is created, resulting in the weld connection; this is the end of the welding phase. The entire welding process takes around 18 seconds.

To finish the welded joint an automatic milling mechanism is provided on the internal centre clamp to remove the internal welding burrs so that the inner wall is smooth at the level of the welded joint. A device is also provided externally to remove the external welding burr in order to be able to place a perfect coating cover on the pipe.

Error-free welding can be achieved by controlling the welding parameters with a process control. Furthermore, by recording these process parameters the quality of the welding is formalised and assured. The research phase we are currently going through is necessary to qualify the welding procedure in accordance with international standards and the prevailing conditions in the industry for pipeline welding.

This fully automated welding method has many advantages over conventional fusion welding. Firstly, the heat input is limited by the very short welding time. By expelling the impurities through the welding burr, the heat-affected zone (HAZ) is very small. Furthermore, a recrystallisation and grain reduction occur in the HAZ through the forging and transformation that take place. This provides an improvement in impact toughness in the zone.

The welding process requires few operators and can be performed with limited staff. The process is a sustainable technological development, as welding gases and radiation are not released and the process can be performed with minimum energy consumption.

The automatic quality recording improves traceability and quality control. This welding method is a groundbreaking transition in the conservative world of pipeline construction.

ANDERE PROJECTEN